FIRST THINGS FIRST!!!

This room is run off dues... all the dues go back into this room for repairs and improvements. They don't go to Reliance. When there is little damage there are lots of improvements and vice versa. Anyone trying to beat the system down there is only beating their fellow user.

The shop is not designed to run your business out of! Nor is it intended for you to pull a quick high paying movie gig out of. It is designed to back up some missing tools in your own studio shop. Or if you are an actor and want to make a one off art piece for your studio or some other project. Very casual part time use..... even though it could be a dream production shop for your business.

In the past "contractors" would pay the 25 dollars in dues and then do well over 100 dollars in wear and tear that month. This meant Reliance and myself were kept busy playing Santa Claus to three or four "business owners". We have now hung up our red suits. If you have a good paying gig then go buy the tools you need and set up your studio like it should be!!! Don't lean on other shop users and volunteers to prop up your business.

One other thing....

Yes it is a volunteer dictatorship that runs this room the only difference is this dictator gains nothing from any implemented rule or tool improvement. Mostly because I have almost never used it the last 20 years as I have my own stuff set up in my studio. If I had even half a brain I would take it back to the six tools that were originally in there when the building was first built and forget about it...

Now if you want to make the rules down there you just need to convince Reliance to fire me and hire you. If you do seriously make sure you talk to me first! I can give you some very good tips that will help you convince them!!!

So... THE RULES TO START....

RESOURCE ROOM BOSS:

ANDY FROM 106

236-688-2695

Every resource room user will first have to get an orientation from Andy before using any part of this room. What Andy says regarding this room goes! Anyone not listening to him will be in violation of their lease and will be given a massage with the reminder bat as seen elsewhere on this site!!!

FEEL FREE TO TEXT HIM AT ANY TIME TO BOOK IN AN ORIENTATION

RULES SHORT LIST

- To use this room you have to be legally living in the building. No outsiders are allowed to even help you carry something into that room.

- The cost right now is twenty five dollars a month. That goes from when you pay until the end of that month. Or you can pay ten dollars for the last seven days if you are not in a hurry.

- The monthly dues give you access to the shop once a day for no more than two hours.

- The monthly dues give you access to the table saw only. If other tools in there are actually working you can use them for free!!!!

- You must put your name and starting time on the chalk board before you start.

- Once you book the shop it is yours alone for the next two hours.

- No barging in on someone if they have their name on the board unless it is after their allotted time.

- After your allotted time is up you and all your stuff has to leave with you.

- Anyone making more than two cuts on the table saw or other tools has to spend two minutes dancing with the vacuum.

- Absolutely no repairing or taking any tool in there apart except for changing the table saw blade assuming you know how already.

- No using booze or bud etc in there ever. Save that for when working in your own shop if you so choose.

- If you don't know what you are doing then ask Andy or me!!!! Damaged tools can be extremely expensive to repair.

- Remember you are using this room at your own risk!!! Life can't be rewound.

- Absolutely no cutting gluing or assembly on the table saw benches! I know this one don't make sense but will lose you your shop access if you do.

- No changing the dust drum on the dust system! That has to be done by either Andy or myself. No exceptions.

- When the full drum light is flashing then you have to stop using any tools that are hooked up to the dust system

- It is a requirement to read the wall signage and follow what they say.

- Make sure all tools and dust system is shut off before leaving the shop.

- Never shut off shop lights!!!

The ARC Wood Shop Is Available for Any ARC Tenant To Use

No longer will dancers or actors or painters have to feel guilty when using that room as it is now open to everyone no matter what you do or want to do in there. This has the potential to benefit hugely more tenants than it ever has in the past. Now I will admit that the plans and dreams for that room likely exceed my capabilities. At the same time getting it pointed in the right direction doesn't... and now it is pointed in that "right" direction.

Artist Wood Shop Orientation

Before using this shop for the first time you have to do two things. The first is read this webpage top to bottom. The second is you must go through an orientation with the rooms overseer, Andy. This will will only take a few minutes.

To any ARC old timers remember Andy is just relaying rules I have put into place. Please don't dump on the messenger!!! This is set up as a back up to your own wood shop in your studio. It is not for you to run your own business out of.

When Can You Work In This Room?

Any ARC tenant that has paid their dues has access to this room once a day for no more than 2 hours. You can use your two hour segment of time 24/7 making all the noise you want except when it comes to the thickness planer. You can't run that screaming sucker past nine am. Now there may be some case where if you are making too much noise then you might have to adjust that but up until now we have had no problems with noise down there. You cannot exceed your 2 hour limit so you will want to make sure you plan your time in there carefully. Anyone attempting any of the possible "workarounds" for this rule in order to "beat the system" will lose access to this room.

Now The List of Dumb Rules...

How Do You Use This Room?

Ok when you want to use this room here is procedure. You go down to there and check the door. If no one has their name on the door then you put your name on the door and the time you are starting. From that point on you have 120 minutes of access to it all by yourself.

Who Can Use This Room?

To use this room you have to actually be living in the building. In fact any one outside the building can't even help you carry something into this room. Now I know this may seem a little harsh but if you thought a little more about the "lawsuit lottery" and how popular that is today it would make more sense. A lawsuit could shut down this room permanently. That would suck big time. Now even though the odds may be low, if your friend goes in there and doesn't get hurt there's no prize for the ARC!!! If he does get hurt then we could loose it all. I call that "No Prize Gambling" where the winner loses all. It is the path of fools.

What Does It Cost?

To use this room you have to have paid your dues for that month. The dues are per person and not per studio. Everyone using it has to pay. Once you pay me the dues then I activate your fob and you have access. As of now the dues have been lowered from fifty dollars a month to twenty five dollars a month.

Where Do The Dues Go?

Now it is important to note here that the dues do not head off to the coffers at Reliance. No I bank them up and once we have enough dues then I go out and buy some new resources, repair broken resouces, buy new blades, sand paper etc. Thus the more careful you are with the tools in there the less damage. The less damage the more dues we have to put towards improvements. Which in turn benefits you! It is a win win situation.

What Do The Dues Get Me?

The $25 in dues you pay give you access to the room and free use of the table saw only for one full month.

Now if... by chance.... there are any other tools in there that actually work you have free access to use them also. : )

If You Need Help....

If you need help with your project in there you can get another ARC inmate to help you as long as they have paid their dues. If you do this they will be using up their time limit the same as you are. Please remember in this case that the dues used to be $50. per person...

The One Exception To The No Leaving Junk Rule...

That is if it is done by Reliance staff, including myself or Andy who does the orientations and overviews the shop.

His responsibilities are giving all new users orientations, replacing consumables, and keeping an eye on the room, letting me know when tools are not working, letting me know if someone has a hard time with the rules. He also offers up advice and ideas as far as how you can do things in this room. Never hesitate to ask him for help but please remember he is not there to help with your "grunt" work, sanding, construction or clean-up.

What he doesn't do:

- He does not make the rules!!! I make the stupid rules! : )

- Nor does he take flak for the stupidity of the rules. He never made them.

- Nor does he clean up after you! That job is for you or your Mom.

When It Comes To The Rules....

With this room you just have to remember what Andy says is the rule... Not his rule... but mine. Anyone not listening to what he tells them will lose their access to this room. Like I said about this room is run by the dictator that runs this joint.

Now if you don't like this then great! You are now free to buy what you use in that room and set it up in your own studio!!! Every month you will be saving $25. Not only that but you will be doing what the spirit of the ARC is all about. After all that is what these studios were specifically built for. Working first... then living second, right in the middle of your own shop.

Though an even better idea is talking Reliance into firing my sorry ass and then talking them into hiring you!!! I can even give you some great tips on how to go about that. Then you can be the dictator. In the meantime you have to live with my.... dictation. Sucks but it is how it works down here... on earth.

Can You Leave Stuff In This Room?

No.... you can't leave anything in there! When you leave you and all your junk has to leave with you. This rule really sucks! Just the same please remember anything left behind will be disposed of or moved out into the hallway. Once you are done you have to wipe your name off the chalk board. This frees up the shop for the next guy.

What This Room Isn't.

The ARC Shop was designed to fill in where your own studio was lacking. It was also to give you access to tools and other things you might rarely need. Like jumper cables, battery charger, pallet jack, material dolly etc etc. If you did not have say a table saw then you could use the one in there to make your planned cuts. Then eventually when you can afford it, buy your own. Or maybe you want to try out welding then the metal shop is great for that. If you like it the same thing buy your own. Unless of course you only need a couple of welds every month or so.

This room was not was not designed or built for full time every day use. This is an important distinction. You see it could handle about three full time users at best. Some days you will go down there to get that piece done for your customer who wanted it last month and someone will have the welder or whatever tool you need tied up for the day. This often created huge frustration in the past.

The other intention for it was so that painters could go down there once a month and build some stretcher frames and other short term one off projects here and there. Often they were not able to do that due to two or three production users having it booked.

The amount of users this room has gotten in the past is anywhere from 2 to 14 users a month. They come and go depending on the projects they are doing. In the past everyone had to work around each other in there. Some days it would get dangerous busy in there. Now you will be the only one in there working. This is important to note when moving to the ARC.

Can You Repair Tools In This Room?

NO!!!..... ABSOLUTELY NOT.... Anyone doing so will immediately lose access to the room. There are reasons for this beyond explaining here. The only exception is if you have an email from me saying that it is ok and you have double checked with me on the actual day you are going to do it. There are a lot of factors at risk one of them is potential damage to the tool.... The other is liability... Yes I know you know all about that tool but it is not about you. If I let you do repairs then the next guy will think he can also and he doesn't know how. If I talk to you and feel like you do know and thus give you permission then the rest is on me. I will check it afterwards if needed. I have seen users trying to do the simplest tool repairs and do nothing but lose parts and create more damage.

Now you are free, so far, to change the blade on the table saw to your own blade if you are sure you know what you are doing. You can also do the same on the band saw. Though not on the chop saw. Anyone who can "figure it out" in order to do it then they can't for sure!!! "Figuring it out" has cost this room far too much money as it is. Do that with your own tools but not the shops.

No Booze or Bud.....

Anyone caught drinking, using any kind of drugs or especially smoking in that room will loose their access permanently. The last thing we want is blood and bone chips sprayed all over the place! Or worse the place caught on fire.

How To Tell When You Should No Longer Be Using This Room.

So here is how it works down there. If you don't have a table saw you can go down there and use the saw. No worries. When your side hussle, art production sales etc start to take off and you start needing that saw more than maybe two or three times every week, give or take, then you know it is time for you to buy and set up your own table saw in your studio. You see because it is not fair for you to be having the other users help fund your business. No matter what tool you are using they all only last so long. The table saw is around four thousand dollars right now... assuming you can even get one thanks to the bad flue season which seems to be ongoing or supply chains etc. If your extra heavy use wears it out then the dues from other users have to go towards the replacement. Not hard to figure out that is not fair.

Now sure Reliance could pay for that but that just means added expenses on their end which always translate back into increased rents. Meaning again other tenants helping fund your production.

You Have To Know What You Are Doing....

When it comes to using the tools in this room you have to know what you are doing. Someone here might show you the odd thing but no one is giving you any legal schooling. If you don't know what you are doing then you are taking chances. Of course life is all about taking chances. You just want to make sure it is you who takes the chance and before taking any chances it is good to have an idea about the odds. Mostly how much do the odds seem to favor you. It is always good to study dangerous things in advance to using them. This is far better than when you have all the time in the world as your bodily "damage" is healing.

You're In!!!!!

OK... finally, your name is on the chalk board, I am no longer blabbering in your ear, you are inside and the door is locked..... Whew!!!!

Music....

OK in the past we did not allow loud music in there. We still don't if it is too loud but at lower levels you are fine. After all you are the only one in there so no one is going to care you are playing Barry Cantalope or not!!!! Eventually we may even get a sound system in there.

The Old Cut Only Rule....

Also we no longer care if you assemble stuff in there now. Again since you are the only one using it as long as you are out in time no biggie. Now if you are gluing and clamping stuff it still has to go when you do. Thus it is good to have your own carts or dollies for moving your stuff back to your studio. Please don't use ARC carts to move and store your stuff on until the next day when you go back down. You just have to remember that there is NO CUTTING OR GLUING OR ASSEMBLY ON ANY OF THE TABLE SAW BENCHES. This is a hard rule because they are so easy and right there. The bench in the dust room and by the compound miter saw are for gluing and cutting. So is the one over by the chop saw and tool wall.

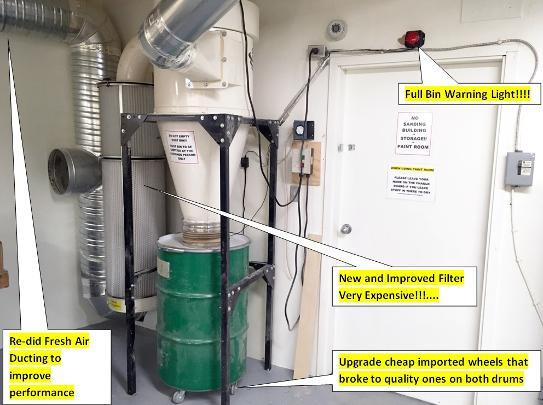

The Dust System

This dust system is made in the USA and was very expensive. The last filter I replaced was barely under $1000 dollars.

Things To Take Note Of!!!!

The Red Warning Light. This light is right above the paint room door. If it is flashing you must shut the dust system off immediately!!! This means the bin is full and if left running will ruin that new thousand dollar filter!!!

No Changing The Dust Drum. When the dust drum is full you need to contact me or Mario to get it changed. Shop users cannot change this drum!!! I know it seems simple but there are complications which again can lead to destroying the thousand dollar filter among other things.

Shut Off The Dust System When Leaving Shop. If you are the last person leaving the shop it is your responsibility to shut off the dust system!!!

The Dust System Should Not Be Turned On and Off More Than Six Times an Hour. There are technical reasons for this according to the manufacturer. Doing this more than six times an hour can heat up the motor excessively potentially causing motor failure.

The Most Important Tool In The Room....

This strange looking beast is one of the scariest tools in the shop!!! Seriously, based on what I see on the camera, it appears this tool is terrifying to a lot of the people! I am not sure why because you can clean up the whole shop in a fraction of the time that a broom and scoop takes???!!! Not to mention a broom and a scoop does about half as good a job and you get to re-breathe in more of that floor dust. If you are not good at math or think you have to wear an apron when using this you are seriously missing out. To vacuum the whole wood side of this room takes about 4.5 minutes.

So PLEASE!!! Do yourself and everyone else who uses this room a favor and use this for your clean up!!!

The Table Saw....

When it comes to the table saw the main thing we want to know is that you are aware of "kick back". This is where the blade grabs a piece of wood you are cutting and shoots it back at you doing about mach 2. Been there but luckily was out of the line of fire. When you get your shop orientation Mario is going to make sure you know about it and how to avoid it. Make sure you understand this concept because the saw will get you on this one far quicker than it will ever cut your fingers off!!! Search it on youtube and you can see some fun videos about it on there if you want. Don't let it scare you though because if you know what you are doing it just won't happen.

Remember: Most people who cut their fingers off on table saws are know it all professionals!!! And this is apparently factoring in the fact that they do more cutting.

Dewalt Compound Miter Saw....

This and the table saw are the two most used tools here. Once again make sure you know what you are doing before using them. If not ask for help. Please don't try to "figure it out" on your own. You can experiment with your own tools but don't with these because they are needed by a lot of people.

Now though it is still in the testing stage the new dust system seems to be working quite well. When you use the saw the sawdust flies back and falls into the garbage can. The fine dust gets sucked into the mini dust system. That system turns on automatically the second you start the chop saw.

Remember no changing the blade on this saw unless you have first talked to me or Mario.

The Belt Disc Sander...

This is a real beauty. We recently changed up the paper on it to 60 grit. You will not believe how fast it removes material now. It will take down hardwood, skin bone etc as if it was not even there. A real time saver for sure.

Now when it comes to this sander you have to make sure that you are running the dust system when using it and that you have the two flaps open. I know you are in a hurry and only have a bit to sand but that is not the point. TURN ON THE DUST SYSTEM BEFORE USING.

17" General Band Saw....

This beauty has been working great since 2007. That's pretty well the life span of most newer tools. Being General we might squeeze some more life out of it. It is a tough looking thing but will be in the land fill long before my 1949 Delta band will be even be worrying about it.... and it is already 72 years old!!!

The one problem we have had with this one is people in the past have left it and then left the shop. When you shut it off it sometimes feels like the off button clicked but really didn't. Since it coasts for so long after shutting it off it is easy to not notice. Thus please watch to make sure it is actually shut off.

Also with this saw make sure you use the dust system with it and open the flaps. You can't miss the signage on it now to do that.

General 6" Jointer....

This one is a real beauty that works great. Again make sure you use the dust system and open the gate valve when using it or you will plug up the pipes.

The General Drum Sander....

This tool is great as long as you seriously know how to use it. Most people don't... especially the ones who say they do. Thus before you can use this tool you have to get a bit of a special orientation for this. You see these tools are very expensive and as most girlfriends have been around will tell you most guys don't have a clue. The trouble is they can't admit it and the tool pays the price. So if you need it let either Mario or myself know and we will talk to you about it.

Important: No sanding finished wood flooring.

General 15" Planer....

This is our planer. Great machine that makes a ton of noise. Thus you cannot run this thing past 9pm at night or before 9am in the morning. Obviously you have to run the dust system when using this machine. Just make sure you also open the dust gate to this machine also.

Important: No planing finished hardwood flooring.

Wood Lathe....

This is something that does not get used much but when it does it seems to work great. Again just make sure you know what you are doing and not just trying to "figure it out" the people that do use it need it and don't need you experimenting with it.

The General Square Holer....

OK maybe not the right name but this tool is handy for those guys always trying to drive square pegs into round holes. Again know what you are doing before using it and as with any tool nothing ever needs forced unless you are doing it wrong!

Dewalt Scroll Saw....

This saw has been used very little. We might make this mobile so that you can sign it out for a small fee and use it in your studio.

Wood Drill Press....

This useless piece of junk kind of works but is dangerous. I have been trying to track down a good pre-plastic one but they are getting harder to find lately.

Drill Bit Sharpener....

This drill bit sharpener is incredible. I have one myself and it is a godsend. Good luck trying to figure it out. You seriously need to follow the instructions or youtube video but once you get it down they are the best score ever. On top of that they seriously do pay for themselves in no time flat. It takes a while to get onto using but once you do it enough it sticks... probably take you less time than it did me to make it stick also.

Chisel Sharpener....

This tool is like the drill bit sharpener... instructions needed.... but man when you figure it out you will be impressed!!! You can get a super pro looking two angle edge on your chisels and sharp as hell.

Metal Band Saw....

This is a pretty good saw for cheap imported crap. There is only one problem with these and that is the feed speed. If you put too much downward pressure on the blade while it is cutting you just burn out the forty dollar blade. Most people think metal cuts like wood for some reason.... Thus often someone will pay their meager dues and then burn out a 40 dollar blade in ten minutes.

Makita Metal Chop Saw....

These work great for making quick cuts on steel. This one has had the traditional blade swapped out for a very expensive diamond blade to reduce the amount of dust that it gives off. After all in the sad state of California that dust is carcinogenic. This is a great metal chop saw.

General Drill Press.....

This drill press is for drilling metal only. It is definitely not recommended for drilling exotic woods you have paid a fortune for. Mostly because odds are good that it could have some oils or cutting solvents on it that could stain your priceless piece of rare jack pine.

Miller Plasma Cutter.....

This cutter is great if you want to cut two pieces of steel out of one. Once again this is an expensive tool so if you want to use it you need to know what you are doing.

Miller Wire Feed Welder.....

This is one of Miller's more popular welders. Works great as long as you know what you are doing and have a bottle of gas. As of now you need to have your own gas bottles.

Canox ARC Welder....

Now if you don't have a bottle of gas and need to stick two peaces of metal together this puppy is exactly what you need. No complication as long as you have welding rods.... which we provide. At least the basic ones. Of course you have to know how to use this welder to get good welds but you would be surprised what these old welders are capable of. The infinite setting on this one is what makes it so good. You can tweak the amount of amps by small amounts until you get it just perfect.

Ingersol Rand Air Compressor....

This compressor is actually a pretty good one. First off it puts out all the air you would normally use in a shop like this. It is important that this compressor be left on at all times. It also needs to be drained every so often. That gets done by Mario normally. Though if you are using a lot of air as in the sandblaster then you may have to do it more frequently.

Vintage Brown Boggs Step Shear

This vintage beauty works like a dream. It makes the nicest cuts ever on anything up to 18 gauge sheet steel. I found it would perfectly cut the thin pages I tore out of my bible as if it were a paper cutter. At the same time I cut some 20 gauge sheet steel just as easily. It is definitely a bonus to have even though not something you might need that often.

PLEASE NOTE: Trying to cut anything other than it was intended for will only lead to damaging this vintage gem. This would ruin it for everyone else. So please ask me before you try "experimenting" with this tool.

Sandblast Cabinet....

This is a cheap imported sandblast cabinet but does work fairly well now that I did some modifications to it. I changed the light in the cabinet to one that actually works. I also redesigned how your change out the windows which is extremely easier now.

Please remember sandblasting is a deadly game with the wrong media. So before you blunder forth it is a good idea to read up on the process first. There are many different types of media that will get you totally different results. It is also vital to wear a good mask while using this. Even though it is designed to handle most of the dust what it misses could kill you later on in life when your immortality wears off!!!

Remember two types of people get hurt using tools. The pro's who think they know everything and the beginners who think they can figure it out via experimenting.

The bottom picture shows where we keep the replacement windows that I have pre-cut Once the window is too hard to see through you can change it out by opening the frame around the window and pealing off the old window and taping in the new one. Then put the lid back down which has powerful magnets to hold it in place.

Boat Anchor....

This is an imported boat anchor. They are great for any kind of larger boat. The odd shape makes them grip the ocean floor. Now since we did not have a boat and were under the impression it was actually a tool I decided to finish the manufacturing process. Mostly to see if it would work for something. Turns out it actually does... kinda.... For now we are going to keep it around a little longer. I have used it to roll some sheet metal once and it did save the day. Like most imported tools it looks serviceable but actually isn't.

Big Bad Bench Grinder.....

This 3/4hp bench grinder is a bit of a pig. Cheap imported version of the real American made ones from daze gone by. It does though work. The belt sander on this will remove metal about five to ten times faster than a stone will. It is also hugely safer and the belts never break. If you break a belt on this you are doing something radically wrong.

With this tool the only thing that slows down the speed of material removal is pushing too hard. This is what fools do. Lighter and steady is the fastest way to remove the most material you can. I have used the one I have in my studio for at least 12 years and love it.

Changing the belts is very quick and easy. So is centering the belt on the wheels. Before using this tool make sure you know how to do this.